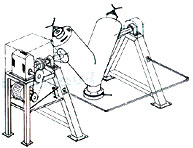

DOUBLE CONE

Efficient and versatile, closed container blender for granular and dry powder material mixing and blending.

Stand alone, Modular construction with gear trains for Models upwards of 750 its production units.

Bectochem Double Cone Blenders are also available with quick clampable, detachable bodies for sterile powder Blending, in Sterile areas, and for ease in autoclaving the body. Models range form 15 lts to 6000 lts production models. Optionally conical adaptors with universal joints for Container Bin clamping and loading of Blenders can be provided on customer demand. Applications range from Pharmaceutical, Cosmetic, Bulk Du\rug and Chemical, Dyes, Intermediaries Animal feed, Food, among others.

|

|

|

|

|

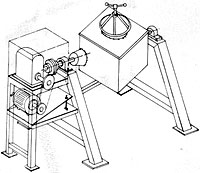

V BLENDERS

Rotary, tumble type Blender with manholes for product loading. Cylindrical 'V' curves allows easy access to the internal areas for better cleaning. The typical 'V' shaped allows for higher shear of mixing without attrition and particle regeneration, leading to shorter Mixing/Blending times. Ideal for fragile granules and in formulation where fine percentages need to be highly controlled. Due to frugal and simple design these Blenders are a maintenance Engineers delight, Unit can also be retrofitted with conical adaptors with butterfly valve for clamping of IPC for dust free, easy loading and discharge. Units available in model from 50 its through to 2500 its capacity and in materials of construction according to customer requirements. |

CUBE BLENDER

Another versatile Blender, similar to Double Cone and 'V' Blenders. The special degree of mounting the Cube allows for shorter operational duration as the sides and corners of the cube act as baffles and disturb the internal flow of materials. Units are widely used in pharmaceutical, cosmetic, food, animal feed industries as they are more compact. Manholes provided, allow easy access to the internal areas for faster cleaning and change over.

Bottom valve allows for easy and faster discharge of dry powder. Models range from 100 lts to 1000 lts in various materials of construction. |

|

|

|

|

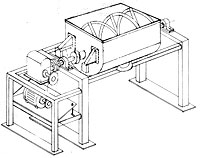

RIBBON BLENDER

Ideal Mixer for homogenising products of various type and size. Good for distribution of liquid, fragrances and slightly pasty components in micro dossages on to carriers. units primalary consists of 'U' shaped trough horizontally mounted, with longitutional shafts with twin bladed construction Models range form 25 lts to 6000 lts production units. Optional jackets for heating and cooling, choice of various material of constriction, central end discharge design and various stuffing box design can be provided to meet specific customer requirement. Bectochem Ribbon blenders can handle many products including Pharmaceuticals, Foods, Animal Feed, Condectionary, Chemicals. Fertilizers, Plastics, Cosmetics, Pigments, Insecticides. |

PLANETARY MIXER

Hundereds of Bectochem Planetory Mixer are at work today on process lines across the world, producing vast variety of products and handling materials from simple mixtures to Sophisticated reactions involving, internal pressure, controlled temperature.

Stirrer design and orbital rotation lead to optima; mixing effieciency ensurring homogeneous mix as the heater covers every point of the Bowl. Units are available in lab model of 10lts through to 1000 lts capacity in various materials of construction mechanical seals for stuffing box alternatively mechanical seals for particular applications. Usage varies from Liquid-Liquid, Liquid-Solid, Solid-Solid Mixtures catering to almost all industries, barring a few.

In the Unique change can design the bowl can be easily removed for remote discharge cleaning and further processing.

Units with Jacketted Bowls for heating and cooling can also be provided. Drive heads can be raised and lowered by manual, hydraulic or electro mechanical means. Flame proof constructions can be provided. |

|

|

|

|

BATCH MIXER

Provide quick and efficient mixer for a complete range of powders and particulate materials.

Incorporates a jackable tumbling device and a separate, removable container. Gentle tumbling motion minimises degradation of the products and batch integrity Containers can be conical bottom, cyclindrical, for size upto 500 lts and square with bottom cones for higher size.

Detachable BIN/CONTAINERS enable charging/ discharge to be done in separate area, minimal dust generation and closed transfer mechanisms for better GMP.

These Blenders are ideal for Pharmaceuticals and Food, Animal Feed, Confectionary industries and are available in Models from 300 lts to 2000 lts. Development models are available on demand along with choice of materials. |

OCTAGONAL BLENDER

Present day Dry powder Blender, widely used in Pharmaceutical and food industries. Ideal for dedicated production campaign, units designed for Bins charging and discharging systems, for dust fress operations. Ideal for low cieling areas.

Specially designed and constructed body allows for slow tumbling, leading to shorter mixing periods vis a vis Double Cone and Cube Blenders without degrading powder structure. Model range from 25 lts to 5000 lts in various materials of construction. The special shape of these units allow for reduced motor HP and low running costs as compared with other units. More than 100 units are in operation in industries like Food, Dairy, Pharmaceutical, Pesticides, Dyes, Drugs, Chemical Industries. |

|

|

|

|

VERTICAL BLENDER

Establishment in 1842, in Rochester, New York, USA, CHARLES ROSS & SON CO. is today arguably the leading manufacture of Mixing, Blending ,Dispersion Equipment's in North America. The BECTOCHEM ROSS Alliance between two highly vibrant organisations, hearlds a new era in the launch of such equipment as the Vertical Blenders, offering modern day technology for these equipment's at your doorsteps.

The Vertical Blender is a Versatile Blender / Mixer used in a wide range of applications. Its unique triblending action achieves the shortest possible mixing times. The mixing Screw moves material upwards and in spiral motion. The upwardmotion is combined with a secondary interna; movement along the periphery. The typical conical shape of the Vessel helps in cascading material from top to bottom.

Ross Vertical Blenders are available in sizes from a popular 35 lts lab unit to 15000 lts production models. Vaccum and Non-Vaccum application with heating and cooling jackets are available along with Dry/Distilling systems based on user specifications and suitable for Adhesive, chemical, Coatings, Cosmetic, Food, Pharmaceutical and Plastic Industries. |

Ross Blenders have the unique advantage of:

- Efficient mixing.

- Complete discharge.

- NO PINTAL Bearing at bottom due to improved Swing ARM design.

- Full load start up.

- Low Floor space.

- Reduced HP leading to lower operational costs.

- The unit comes with the complete back up support of BECTOCHEM & ROSS Customer service, all across the globe.

|

VACCUM & JACKET

This 3 cu. ft. machine is designed for operation under vaccum and internal pressure to 90 psig. The unit is constructed in stainless steel and is provided with a 125 psi jacket which is insulated and sheathed. A2" sampling port is mounted thorough the cone wall near the bottom and a manually operated valve is mounted on the bottom for complete discharge of blended materials. |

|

|

|

|

LABORATORY SERIES

A standard 1 cu. ft. model is available for small production or development activities. The unit includes a conveniently raised and lowered cone, vaccum construction, a jacket for heating or cooling, stainless steel surfaces polished to a 140 grit finish and a variable speed drive. |

ADVANTAGES OF ROSS VERTICAL BLENDERS

Efficient Mixing

Vertical Blenders typically complete a blending cycle in approximately 1/3 the time of conventional blenders.

Complete Discharge.

Blended materials move to the bottom discharge valve by gravity for nearly 100 percent discharge.

Low Power Consumption.

120 cu. ft. units require only 10 HP vs. 25 to 30 HP on horizontal blenders.

Improved Swing Arm Design.

The internal swing arm is specially designed to allow thermal expansion and a more reliable machine when used for mixing at elevated temperatures.

Unsupported Mixing Screw

Many models are designed to operate without bottom screw supports.

Starting Under Load.

Full load starting is possible with the machine as the screw is normally started and materials are placed in motion before the orbiting motion of the screw begins.

Low Floor Space Required.

Since units consume little floor space, users can free up space for other plant operations. The configuration of the mixer is uniquely ideal for multi-floor or mezzanine operation and smooth material flow.

Gentle Mixing.

The slow speeds of the mixing screw and orbiting arm assure a gentle low shear mixing action that does not degrade sensitive raw materials used in the process.

No Heat Build-Up.

The low horsepower and shear forces of this machine minimize heat build-up and the degradation of sensitive materials.

VACUUM DRYING SYSTEMS

Complete Vacuum Drying Systems are available to suit the need of the individual user. The systems are typically provided with a filter, condenser, vacuum pump and condensate receiving vessel. Complete control packages as well as heat Transfer Systems are also available. |

|

|